The textile industry is constantly evolving, with new materials, techniques, and technologies emerging every day. As the global demand for high-quality prints, durable fabrics, and eco-friendly dyeing methods continues to rise, it is becoming increasingly important for printing businesses, textile professionals, and international buyers to understand the differences between sublimation disperse dyes and normal dyes. In this blog, we will explore the advantages and limitations of both categories of dyes and highlight how choosing the right type of dye can simplify production and enhance product performance.

At SD International, one of the best disperse dyes manufacturers, we understand the importance of making informed decisions when it comes to selecting dyes for different fabrics and end-use applications.

We have extensive experience in the industry and are well-versed in the properties and uses of various types of dyes. In this blog, we will delve deeper into the comparison between sublimation disperse dyes vs. normal dyes, and provide you with expert insights and advice on how to choose the right type of dye for your needs.

We invite you to join us as we explore the world of dyes and uncover the many benefits that sublimation disperse dyes can offer. From their unique properties to their wide range of disperse dyes applications, we will show you why they are the preferred choice for many in the textile industry. Whether you are new to the world of dyes or are an experienced professional, this blog will provide you with valuable information and insights that you can apply to your own production processes.

What Are Disperse Dyes?

Disperse dyes are non ionic, water-insoluble dyes that are used mainly for dyeing synthetic fibers such as polyester, nylon, and acetate. They are essentially small, finely ground particles that are dispersed in water with the aid of dispersing agents, as opposed to reactive or vat dyes that are designed to dissolve in water.

Disperse dyes are attracted to hydrophobic fibers and perform best at high temperatures. For this reason, these dyes are excellent choices for sublimation printing.

Understanding Sublimation Disperse Dyes

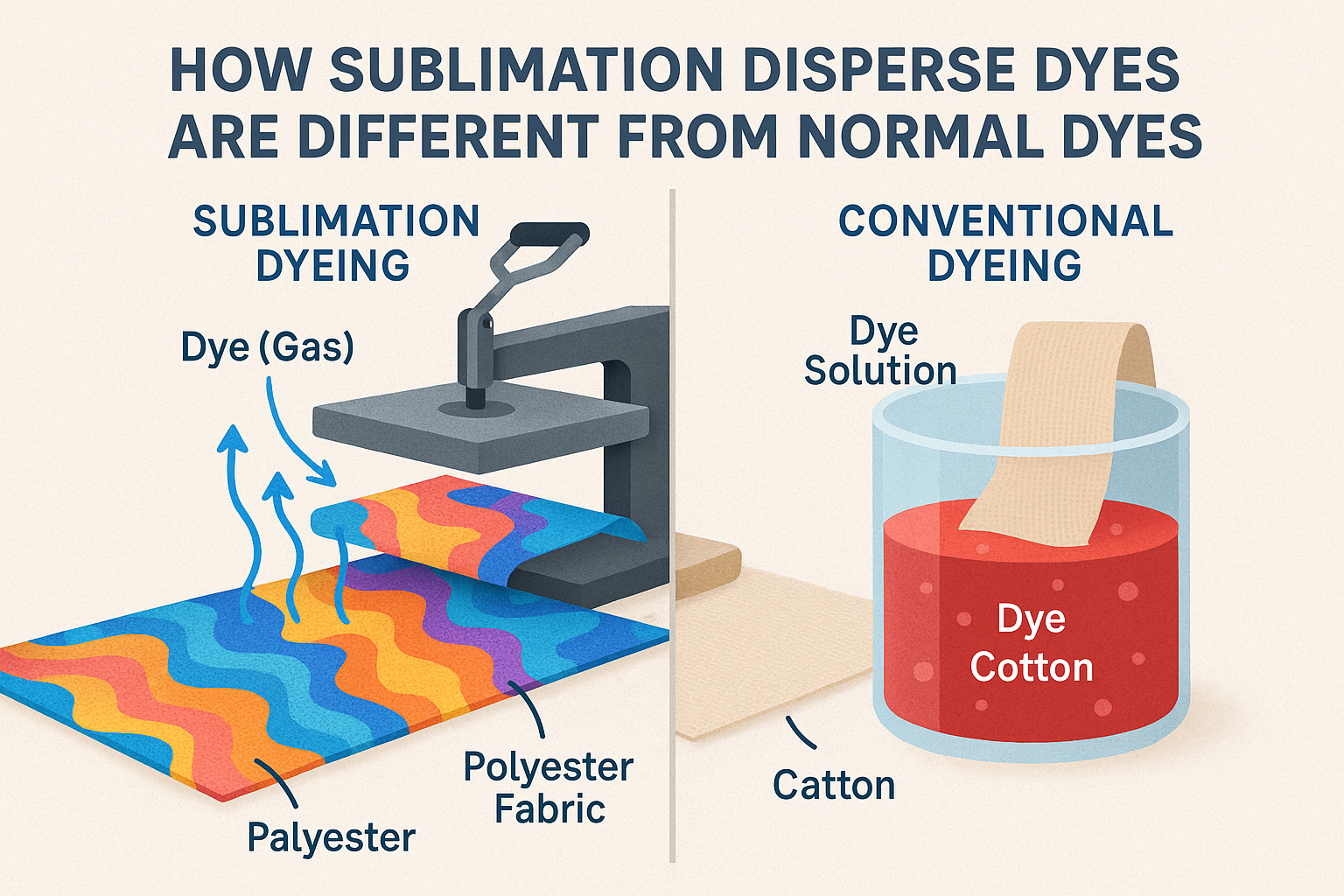

Disperse sublimation dyes are used specifically for the dyeing method known as heat transfer printing. When the dye is heated, the dye will sublimate and penetrate through the surface of the synthetic fabric.

On cooling, the dye-molecules will attach to the polyester fibres, thereby fixing the print onto the material in brilliant and long lasting colours.

Properties of Disperse Sublimation Dyes:

- Suitable for dyeing polyester/polyester-coated articles

- They are used for sublimation printing

- Very good colour fastness and brilliant colours are obtained

- Suitable for all kinds of heat transfer articles like mugs, t-shirts, banners, etc.

Normal Dyes: A Quick Overview

Normal dyes are the typical types of dyes which include reactive, vat, acid, and direct dyes. Dyes for specific fibers are outlined below:

- Reactive Dyes: Dyes soluble in water and form a chemical reaction with cotton and other cellulosic fibers

- Vat Dyes: Dyes which are insoluble, but can be made soluble through a reduction process. These dyes are generally used on cotton and linen

- Acid Dyes: Dyes which work best on protein fibers such as wool and silk

- Direct Dyes: Dyes that can be applied directly to cellulose fibers without a chemical reaction

All of these dyes need to be immersed in water, require different methods of chemical fixation, and often need post processing in order to set the color.

Key Differences Between Sublimation Disperse Dyes and Normal Dyes

1. Process :

Sublimation Disperse Dyes: Dyeing with sublimation disperse dyes is a dry heat transfer printing technique in which the designs are first printed on the transfer paper and are then transferred onto the substrates through heat and pressure.

Normal Dyes: Wet dyeing methods are used that include immersion dyeing in the dye bath followed by chemical fixation.

2. Suitable for :

Sublimation Disperse Dyes : Polyester, acetate, and polyester-coated fabrics

Normal Dyes : Natural fibers like cotton, wool, and silk.

3. Colorfastness :

Sublimation Disperse Dyes: Highly resistant to washing, light, and rubbing fastness

Normal Dyes: Depends on the dye type and requires after-treatment.

4. Environment Friendly :

Sublimation printing: Environmentally friendly, as it uses less water and generates very less waste.

Conventional Dyeing: Generates a considerable amount of wastewater and requires processing before being released.

5. Applications :

Sublimation Dyes: Sportswear, Promotional Items, Flags, Mugs, High-resolution Fashion Prints

Normal Dyes: Apparel, Home textiles, Yarn dyeing, Denim Finishing, etc.

Applications of Sublimation Disperse Dyes in Textile Printing

Uses of Sublimation Disperse Dyes

-

Sportswear and Activewear

These dyes have high colourfastness and vivid shades that make them suitable for sportswear and activewear. The clothing items are subject to repeated washing, rubbing, and sweat and must be highly durable and comfortable to wear.

-

Promotional Items

Sublimation dyes are used in a wide variety of custom promotional products, such as mugs, mouse pads, banners, and more.

-

Fashion Textiles

Fashion designers and brands are using sublimation dyes for high-resolution printing on synthetic textiles such as chiffon, georgette, tulle, satin, and more.

-

Sublimation on Hard Surfaces

If the hard surfaces are coated with polyester, then sublimation disperse dyes are used for customization of gifts, merchandise, and products.

Why Choose SD International – Trusted Disperse Dyes Manufacturers, Suppliers & Exporters

SD International is one of the most trusted disperse dyes manufacturers in India that has all the advanced manufacturing, quality testing, and global shipping solutions required by the textile and printing industries to fulfill their business needs. The company provides:

- ISO and REACH certified products

- Fully customizable shades and solutions

- A network of disperse dyes suppliers and distributors across the world

- Raw materials of high purity and full environmental compliance

- The best technical support with excellent logistics

SD International has the experience and an ethical commitment to be sustainable and innovative to be the preferred partner of all disperse dyes exporters and manufacturers.

Conclusion

SD International has compared sublimation disperse dyes and normal dyes to show that each has its own specific use in textile manufacturing. The unique qualities of sublimation disperse dyes make them a more efficient and eco-friendly option for textile printing with vibrant color results, particularly for polyester. In comparison, vat or reactive dyes, which are normal dyes, are better suited for dyeing natural fibers.

If you are in need of reliable disperse dyes suppliers, or exporters for sublimation or textile printing, then look no further. SD International has quality products, worldwide service, and technical expertise to help grow your business.

FAQs

Q1. Can I dye cotton with disperse dyes?

No, it is not possible. Disperse dyes have a low affinity to natural fibers such as cotton. Reactive dyes or vat dyes are the preferred choice for dyeing cotton.

Q2. What are the benefits of sublimation printing?

The benefits of sublimation printing are brighter, long-lasting designs, excellent wash fastness, and an eco-friendly process that uses less water.

Q3. Are sublimation disperse dyes environmentally friendly?

Yes, sublimation disperse dyes are considered to be more environmentally friendly than conventional dyeing techniques. They produce little to no waste and do not pollute water.

Contact SD International for bulk orders, custom shade development, and global shipping.